Streamlining Logistics: A Deep Dive into Cross-Docking in the Heart of Chicago

Unilogicgroup

December 15, 2023

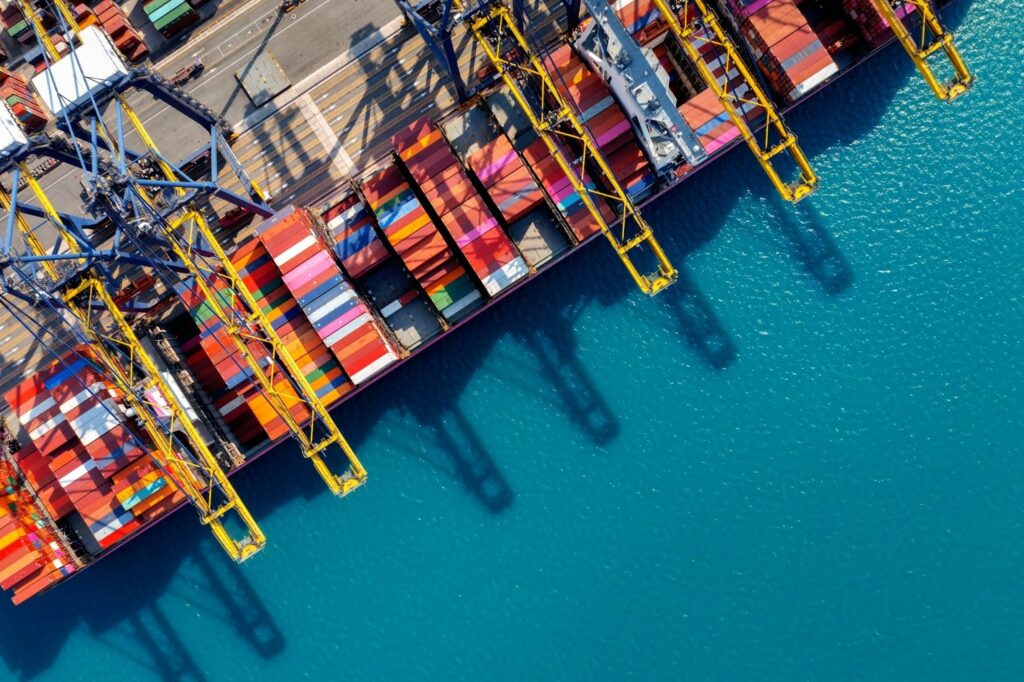

Ever wondered how goods swiftly move from point A to B without getting stuck in traditional warehouses? That’s the magic of cross-docking, and we’re here to demystify it for you. Picture this: instead of products lingering on shelves, they seamlessly transfer from inbound to outbound shipments, making the logistics dance efficient and fast.

In the heart of Chicago, Unilogic Group takes this logistical symphony to new heights. Our cross-docking expertise isn’t just about speed; it’s a strategic move that slashes storage costs, accelerates delivery times, and elevates the entire supply chain. Join us as we navigate the simplicity and brilliance of cross-docking in the Windy City, where Unilogic transforms logistics into a seamless journey.

Decoding Cross-Docking

Ever wondered how products reach you so quickly without hanging out in storage? That’s the magic of cross-docking. Picture this: goods go straight from the manufacturer or a transport mode to you or another mode, skipping the storage pitstop. The goal? Slash costs tied to storing stuff in between trips. It’s like a quick-change artist for transportation, sorting and combining materials efficiently. All this happens in a distribution docking terminal, a hub where trucks dance in and out with minimal storage space.

chains smoother. It involves unloading goods from incoming shipments and swiftly loading them onto outgoing ones, avoiding the storage pitstop. Companies love it for speeding up deliveries, optimizing inventory, and trimming down on transportation and labor costs. It’s logistics simplified, making the journey from point A to B quicker and more efficient.

Types of Cross-Docking

Cross-docking comes in various flavors, each tailored to specific needs. Let’s break it down in simple terms:

- Continuous Cross-Docking

What it does: Swiftly moves goods through a cross-dock facility with minimal or no storage time.

How it works: Products hop from incoming trucks straight onto outbound containers, heading directly to their final destination.

Best for: High-demand products like food, where speed is of the essence.

Key requirement: High coordination among suppliers, carriers, and the cross-dock operator.

- Consolidation Cross-Docking

What it does: Merges smaller incoming shipments into a larger outbound load.

Why it’s used: Reduces shipping costs by sending one big load instead of multiple smaller ones.

Process: Goods are temporarily warehoused until a full truckload is ready for shipment.

Who uses it: Businesses, especially logistics companies transporting small loads or international freight forwarders optimizing container shipments.

- Deconsolidation Cross-Docking

What it does: Splits a large incoming load into multiple smaller shipments for customer delivery.

An example: Parcel carriers bring a big shipment across the country, then divide it into smaller loads for individual deliveries.

Who uses it: Retailers receive large shipments at distribution centers, breaking them down for delivery to individual stores.

In essence, continuous cross-docking speeds things up, consolidation cross-docking saves on shipping costs, and deconsolidation cross-docking efficiently breaks down large shipments for broader distribution.

Each type serves a unique purpose, offering flexibility to businesses based on their specific needs.

Pros of Cross Docking

Accelerated Deliveries: The primary advantage of cross-docking is speed. By bypassing the traditional warehousing pitstop, goods move swiftly from inbound to outbound shipments, reaching customers at a lightning pace.

Cost Efficiency: Cross-docking slashes storage costs. Without the need for extensive warehousing, companies save on space, labor, and associated overheads, making it a cost-effective logistics strategy. Furthermore, streamlining the logistics dance reduces transportation costs. Goods move seamlessly, minimizing the need for additional handling, storage, and associated transportation expenses.

Optimized Inventory Control: With minimal storage time, inventory control becomes more precise. Companies can swiftly move products, reducing the risk of overstocking or outdated inventory.

Efficient Retail Distribution: Retailers benefit significantly from cross-docking, as it allows for the consolidation of products from multiple suppliers and efficient distribution to retail stores, enhancing the overall supply chain.

Cross-Docking Excellence in the Heart of Chicago with Unilogic Group

In the bustling landscape of Chicago, a city known for its vibrant logistics heartbeat, Unilogic Group stands tall as a leader in cross-docking and logistics innovation. Nestled in the strategic hub of transportation and commerce, Unilogic leverages the dynamic spirit of Chicago to redefine how goods flow through supply chains.

Chicago’s significance as a logistical epicenter is undeniable, and Unilogic strategically positions itself at the forefront of it. The city’s central location and robust transportation networks make it an ideal hub for efficient cross-docking, and Unilogic capitalizes on this geographical advantage. We bring unparalleled expertise to the table. As a leader in logistics and cross-docking, we have mastered the art of seamless transitions, ensuring goods move swiftly and accurately from inbound to outbound shipments.

In essence, Unilogic Group emerges as the frontrunner in Chicago, where logistics meet innovation, and cross-docking becomes an art perfected through experience, technology, and an unwavering commitment to excellence.